Idlers & Pulleys

Idlers & Pulleys

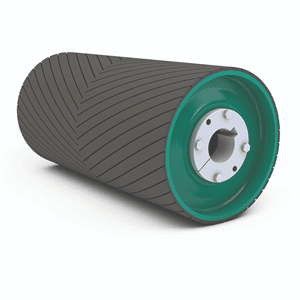

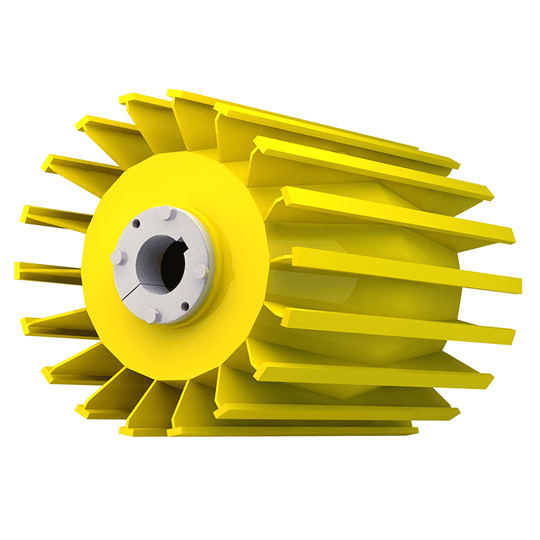

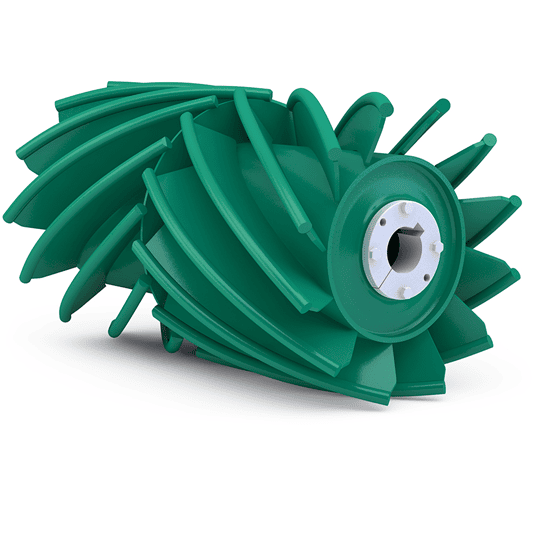

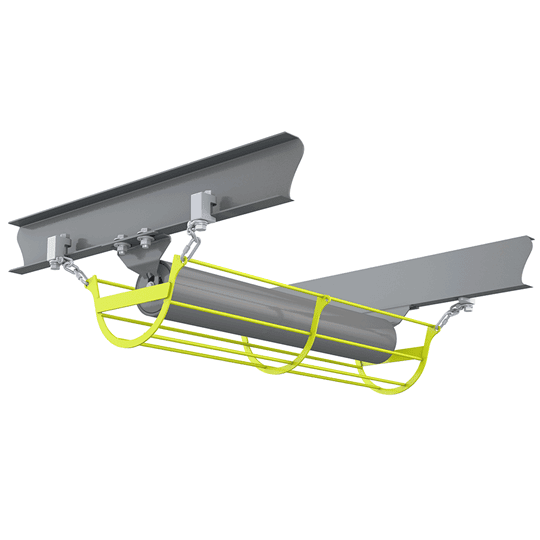

From troughing to training configurations, our inventory includes idlers and pulleys built for strength, alignment, and minimal maintenance. The lineup features impact, return, self-cleaning, drum, wing, and lagged models, ready to support any conveyor setup.

We proudly distribute components from Precision Pulley & Idler (PPI), including rollers, lagging systems, take-up frames, bearings, and telescoping assemblies. Whether you’re designing a new line or retrofitting aging equipment, PPI’s engineered solutions provide consistent performance and reliability.

For custom needs, we also offer plastic idlers with tailored design and fabrication options—ideal for specialty applications or lightweight material systems.

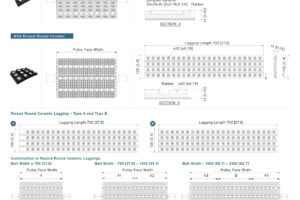

Pulley Re-Lagging Services

Worn pulleys don’t always need full replacement. With our in-house re-lagging capabilities, existing pulleys can be stripped, prepped, and re-covered with fresh lagging—saving valuable time and reducing system downtime. Whether restoring grip with rubber or upgrading to ceramic lagging, this service keeps your operations moving without the wait of new manufacturing.

Rumelca & Motorized Pulley: Clean Power for Food & Agriculture Systems

Rulmeca’s enclosed motorized pulley systems offer a streamlined, hygienic solution for conveyor applications where space and sanitation matter. Designed without external motors or gearboxes, these units are ideal for food processing and agricultural environments—reducing maintenance needs while maximizing efficiency.

The visual below links to detailed specifications, product features, and installation information—perfect for engineering reviews or sourcing decisions.

Thaman Rubber Surface Protection Solutions: Sealing Bearings, Pulleys & Components from the Inside Out

Extend the life of your equipment with Thaman Rubber’s rebranded thermal coating system—engineered to defend exposed conveyor components against corrosion, moisture, and debris. Ideal for harsh industrial environments, this preventative maintenance solution creates a durable barrier that helps reduce breakdowns, extend service intervals, and keep operations running clean.

View the guide to explore how Thaman Rubber’s spray-on protection can be integrated into your conveyor reliability strategy: Enviropeel